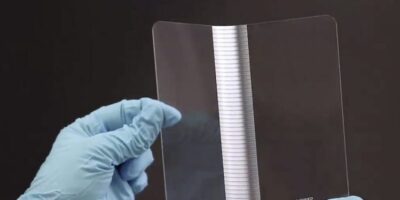

LPKF demonstrates fatigue-free folding glass displays

The smartphone market’s latest trend is foldable displays, currently made of plastic and prone to scratches, wrinkles and premature breakdown and malfunction. Conventional smartphone displays are made up of at least two layers of tempered glass and therefore cannot be folded easily. LPKF Laser & Electronics believes it has the solution which it will present at the SID Display Week conference in San Jose, California, USA (14 to 16 May).

Laser-Induced Deep Etching (LIDE) allows for deep features in thin glass. For the first time, says LPKF, it is possible to realise modifications over the entire glass thickness with individual laser pulses, to create deep structures, such as through holes or micro sections, without requiring special glass and with no chipping or micro cracks.

Its LIDE technology enables the economical production of microstructures in glass without creating microcracks or stress in the material. Using microstructures at the ‘seam’, glass can be bent and folded without fatigue and surface defects.

LPKF Laser & Electronics manufactures machines and laser systems used in electronics fabrication, medical technology, the automotive sector, and the production of solar cells. Around 20 per cent of the workforce is engaged in research and development.