Editors Blog – Sensor technologies monitor energy without breaking a sweat

Advances in materials mean sensors can measure without a body’s sweat obscuring readings or harvest energy from movement to power data handling. By Caroline Hayes

When it comes to exercise, I usually abide by the maxim “Horse sweat, men perspire and ladies gently glow” as my excuse for lack of progress. This is not pure idleness, because a common problem for wearable microfluidic sensors which measure exercise intensity, is that sweat can obscure the readings. Perspiration is analysed for the state of a person’s health, for example hydration levels, electrolyte balance and as an estimate of the level of lactic acid in the blood which can predict muscle fatigue.

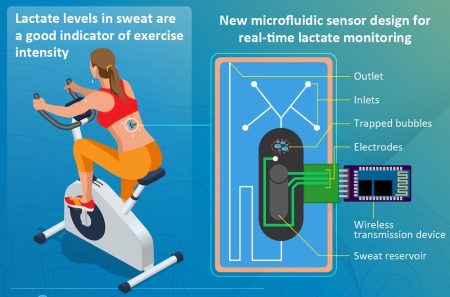

Wearable sensors can monitor biomarkers such as sweat lactate and use microfluidics technology to convey minuscule amounts of sweat to tiny chemical sensors, which transmit measurements wirelessly and in real time. The problem is that air bubbles in perspiration can upset the measurement. Researchers at Tokyo University of Science (TUS) in Japan, led by associate Professor, Isao Shitanda have published the results of their project to develop a wearable sensor which traps bubbles and prevents them from overing the sensor’s electrodes and interfering with continuous monitoring.

Hubble bubble, no trouble

The team developed a microfluidic sweat lactate sensor whose measurements remain unaffected by air bubbles.

Figure 1: The air-bubble-insensitive microfluidic lactate biosensor study was co-authored by Dr. Masahiro Motosuke, Dr. Tatsunori Suzuki, Dr. Shinya Yanagita, and Dr. Takahiro Mukaimoto from TUS.

The air-bubble-insensitive microfluidic lactate biosensor is based on a conventional lactate oxidase sensor attached via double-sided tape to a microfluidic system made of a silicone polymer. When the person wearing the device begins to perspire, the sweat enters the microfluidic channels via four inlets and flows toward a reservoir which is located close to the electrodes. There is an outlet to expel perspiration before new sweat enters. The structure also includes a small wireless transmitter which reports the measured lactate levels.

The design is not groundbreaking in using a reservoir but in incorporating a longer than usual one. The proposed design creates space of approximately four microlitres to trap any air bubbles that infiltrate the device and prevent them for contact the sensor’s electrodes, says Dr Shitanda.

Tests in the laboratory including injecting bubbles into the device during measurement functions to confirm that the reservoir trapped the bubbles during measurement. Tests also showed that measurements were not affected by the rate of perspiration flow. The response of the sensor remained stable for approximately two hours. When the sensor was used on a volunteer exercising on a stationary bike for almost an hour, the sensor showed a lactate concentration correlation ranging from 1 .0 to 50mM as well as a correlation between sweat and blood lactate levels.

“Since the microfluidic system of the proposed lactate sensor is fabricated from a soft, flexible, and non-irritating material, it could be used to continuously monitor lactate levels in sweat, especially in sports and medicine,” observes Dr Shitanda. “Wearable lactate sensors may become useful condition management tools in sports such as soccer and basketball, allowing team managers to know when it’s best to replace a player.”

Go for graphene

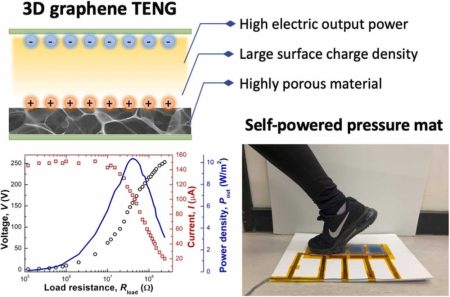

The flexible nature of the sensor material also plays a part in a development by researchers from the Institute of Thin Films, Sensors and Imaging (ITFSI) at the University of the West of Scotland (UWS). They used Gii, a 3D graphene foam material developed by Integrated Graphene as an active layer in a triboelectric nanogenerator (TENG).

Integrated Graphene tailors Gii for specific applications. The research, published in ScienceDirect, shows that the force of a human footprint on a pressure-sensitive mat, equipped with Gii-TENG sensors, can produce enough energy to anonymously identify people entering or leaving a room (Figure 2). This could optimise energy resources in buildings for occupancy and HVAC but there is also the potential for use in wearable devices, where energy from the wearer can be used to generate performance data. In other words, a runner or tennis player’s movements will generate energy that can be harvested for their own analytics data.

Figure 2: Graphene steps up. Picture credit: Integrated Graphene / UWS

For around 20 years, TENGs have been investigated as a technology for converting mechanical energy into usable electrical energy to power both large and small IoT electronic devices and sensors as well as EVs and drones.

According to Integrated Graphene, the commercially viable use of TENG has been hampered by low durability, limited energy output and inefficiency. The company says that adding Gii to TENG has opened up a whole new world of possibilities, capitalising on its high surface area, porosity, light weight, and superior electrical properties. “The energy autonomous, pressure sensing nature of Gii-TENG has the potential to transform various aspects of our lifestyles, society and economy,” says the company.

In addition to energy harvesting sensors, it could also result in self-powered wearable biosensors for early diagnosis of health conditions including cardiovascular disease, gout and diabetes.

Marco Caffio, CSO, Integrated Graphene said: “With the number of IoT devices interlinked worldwide forecast to reach 100 billion by 2030, there is a clear need for new sustainable energy sources and technologies which can meet the power demand from our reliance on technology for work, life and play. Our Gii-TENG platform could potentially prevent the constant replacement of batteries in trillions of devices, and reduce the utilisation of wires, making the IoT technology of the near future to be wireless and energy autonomous.”