Editor’s Blog: Universities research how material can respond to conditions

Challenging the very fabric of our thinking about wearables, two university projects have experimented with polymers, weave, and weft to create materials that have a multitude of practical uses, writes Caroline Hayes.

Research programmes into smart fabric which respond to heat offer new ways to deal with bumps and scrapes with material that shape shifts for self-repair.

The first project is Canada’s University of Waterloo, where a team has developed a smart material, believed to be the first to respond to two different stimuli – heat and electricity.

The ability to respond to two different stimuli opens up potential applications for clothing which can warm up when the wearer goes from one environment to another. An example would be clothes that can warm up on the walk to work on a cold winter morning.

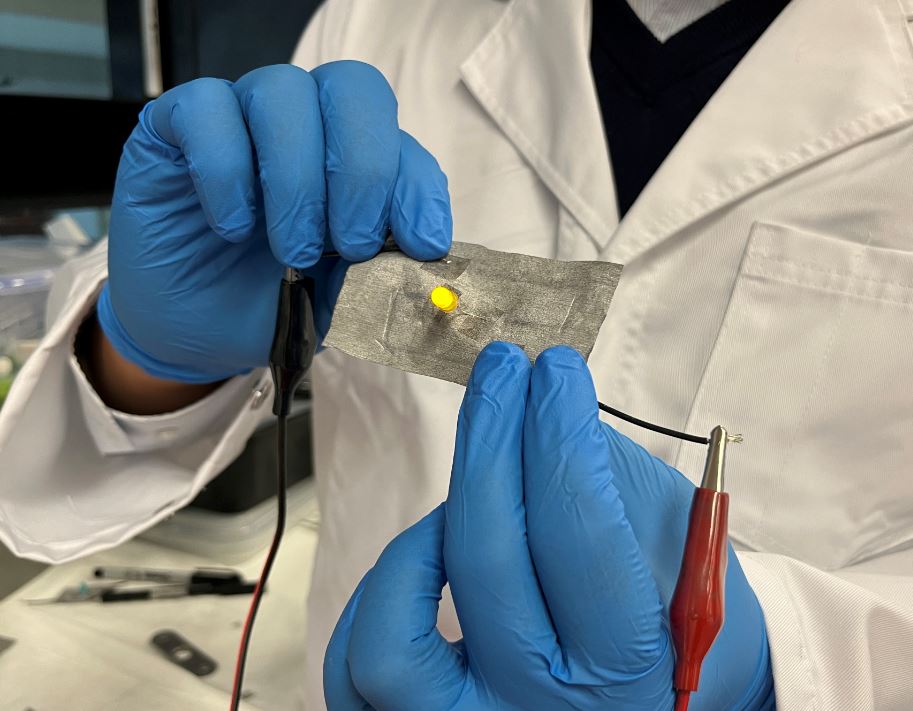

The smart material is made from polymer nano-composite fibres, created from recycled plastics. The resulting combination of engineered polymer composites and stainless steel can change its colour and shape when stimuli is applied. For non-wearable applications, it can be used in vehicle design, for example for car bumpers to regain their original shape after a collision.

Figure 1: The smart fabric created by University of Waterloo researchers is made of plastic and steel fibres. (Photo – University of Waterloo)

Dr. Milad Kamkar, a chemical engineering professor at Waterloo and director of the university’s Multiscale Materials Design centre, said that as a wearable material, it has “almost infinite potential in AI, robotics and virtual reality games and experiences”.

“Imagine feeling warmth or a physical trigger eliciting a more in-depth adventure in the virtual world,” he said.

The fabric was produced on a loom created by the researchers to weave the fabric. It is energy-efficient and cost-effective, said the research team, because it can be activated by a lower voltage of electricity than previous systems. The lower voltage also means it can be integrated into smaller, more portable products which react with their environment for monitoring, such as biomedical devices and environment sensors.

Next, the researchers will work to improve the fabric’s shape-memory performance for robotics use.

Self-healing fabric

An international collaboration with researchers from Flinders University in Australia, North Carolina State University and Sungkyunkwan University in South Korea as resulted in a fabric which can repair itself when cut, monitor a wearer’s electrocardiogram signals and repel bacteria. The liquid metal-coated fabric could be developed for human machine interfaces such as soft robotics and health monitoring systems.

Fabric was dip-coated into a suspension of liquid metal particles at room temperature. The liquid metal particles in the metallic coating layer create conductivity circuits. When pressed with significant force, the native oxide which forms on the particles rupture, removing the insulation it provides and allowing the particles to merge to create circuits that maintain conductivity when stretched.

The researchers found that the electrical conductivity increases when additional coating was applied.

“The conductive patterns autonomously heal when cut by forming new conductive paths along the edge of the cut, providing a self-healing feature which makes these textiles useful as circuit interconnects, Joule heaters and flexible electrodes to measure ECG signals,” said Dr Vi-Khan Troung, medical biotechnology researcher at Flinders University.

Figure 2: The liquid metal-coated fabric developed by at the Flinders University lab.

The liquid metal-coated fabric was also found to offer effective antimicrobial protection against pseudomonas aeruginosa and staphylococcus aureus to act as a protective material which resists contamination if in contact with bacteria. The liquid metal can be deposited and patterned onto surfaces at room temperature. This opens up medical possibilities. Added to which, the particles of gallium-based liquid metals used have a low melting point, exhibit metallic electrical conductivity, high thermal conductivity, effectively zero vapour pressure as well as low toxicity and its antimicrobial properties. Potential applications extend to microfluidics, soft composites, sensors, thermal switches and microelectronics.